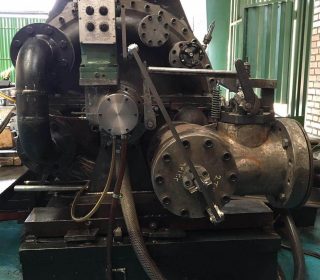

توربین ها از تجهیزات راهبردی به ویژه در صنایع نفت و گاز و پتروشیمی هستند که با اعمال تحریم ها در این صنعت حیاتی و مادر کشور تامین قطعات و تجهیزات با مشکلات اساسی مواجه شد. برهمین اساس و با هدف بومی سازی طراحی و ساخت توربین های بخار زیر 6 مگاوات این طرح تعریف و این شرکت ساخت مجموعه کامل توربین بخار را از سال 1388 آغاز نمود و هم اکنون با دست یابی به دانش فنی و تکنولوژی به روز دنیا، فرآیند طراحی و ساخت این نوع از توربین های بخار بصورت کامل در مجموعه داخلی شرکت انجام می شود.

کاربرد و دامنه تامین

همچنین کاربرد آن ها در بهینه سازی مصرف انرژی، استفاده در سيستم های CHP و بازیاب گرما نیز می باشد.از جمله گروه صنايعی كه از توانايی محصولات و خدمات اين شركت بهره مند گرديده اند صنايع نيروگاهی، پتروشيمی، پالايشگاهی، گاز، قند، مس، سيمان، لكوموتيو و كشتيرانی را می توان نام برد.

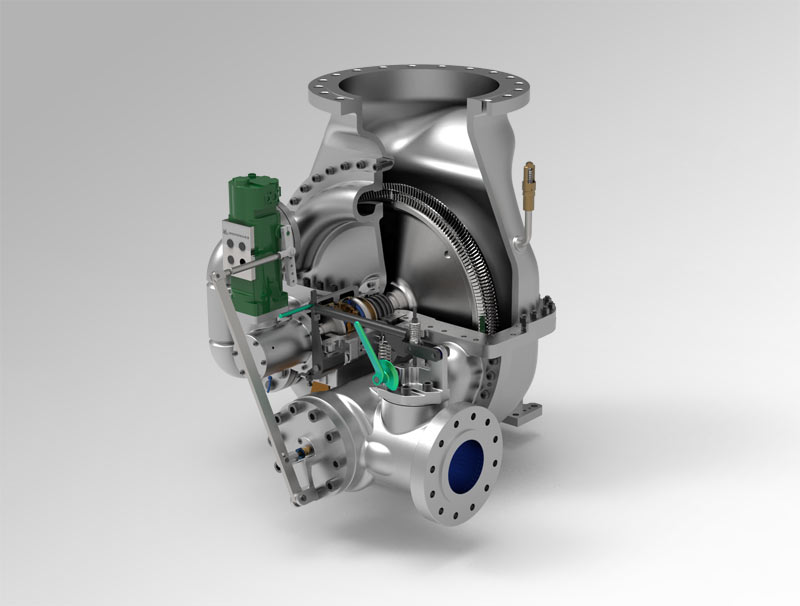

- طراحی و ساخت Skid

- عایق حرارتی و صوتی

- تابلو کنترل ، تابلو محلی

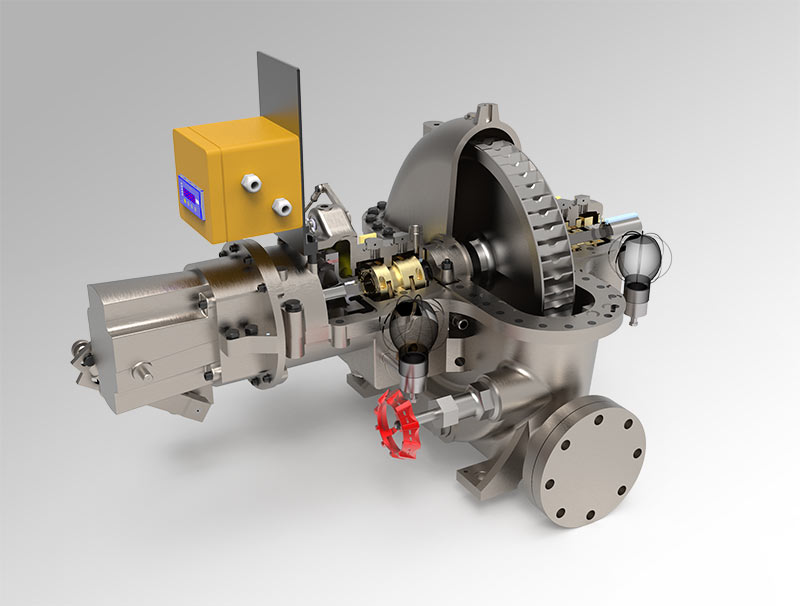

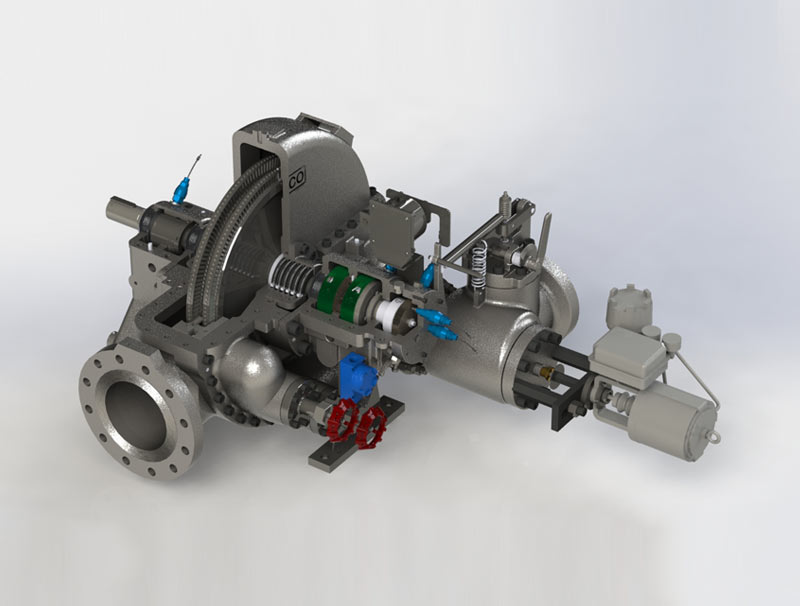

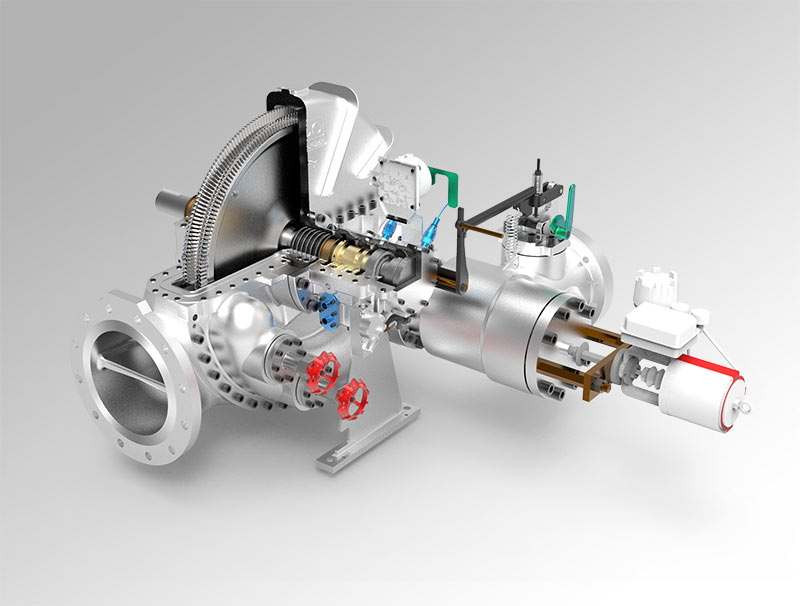

- سیستم کنترل سرعت مکانیکی و الکتریکی

- گاورنرهای مکانیکی ، هیدرولیکی و الکتریکی

- پکیج لوب اویل نصب نیروی ایران مطابق با استاندارد API-614

- تجهیزات ابزاردقیق مانند تجهیزات کنترل دمای بیرینگ ، کنترل ارزش و غیره مطابق با نیاز مشتری و وندور لیست

- سابقه و تخصص این مجموعه به عنوان اولین تولید کننده توربین بخار در ایران

- ثبت در کلیه وندور لیست های اصلی و معتبر صنایع نفت ، گاز ، پتروشیمی و دیگر صنایع وابسته

- طراحی و ساخت مطابق با استاندارد API-611

- کیفیت قابل رقابت با نمونههای مطرح خارجی

- مشاوره فنی جهت انتخاب و خرید

- مشاوره و خدمات جهت نصب و راه اندازی توسط تیم مجرب شرکت

- گارانتی و خدمات پس از فروش

- تامین و ساخت قطعات یدکی

- افزایش راندمان چرخه انرژی و مقرون به صرفگی اقتصادی

ساخت در نصب نیروی ایران

روش تولید و تکنولوژی در نصب نیروی ایران برپایه طراحی و مهندسی بسیار دقیق همراه با فرآیند های کنترلی مطابق استاندارد های روز دنیا و این صنعت می باشد. این اقدامات لازم و سختگیرانه و همچنین قابلیت سفارشی سازی برای هر توربین با توجه به توان و کاربرد مورد نظر مشتری باعث شده است که محصول نهایی این شرکت ازکیفیت بسیار بالا و رقابتی تری در مقابل محصولات روز دنیا برخوردار باشد.

همه چیز در یک نگاه

| 2TY | TY | 3SY | 2SY | SY | BSY | 3FY | 2FY | FY | Specifications (Max.) |

|---|---|---|---|---|---|---|---|---|---|

| 710/49 | 710/49 | 710/49 | 710/49 | 710/49 | 710/49 | 600/41 | 300/21 | 210/14.5 | Initial Pressure (psig/bar) |

| 770/410 | 878/470 | 770/410 | 770/410 | 770/410 | 770/410 | 716/380 | 644/340 | 550/288 | Initial Temperature (°F/°C) |

| 60/4 | 90/6 | 90/6 | 90/6 | 90/6 | 90/6 | 60/4 | 60/4 | 60/4 | Exhaust Pressure (psig/bar) |

| 6200 | 5000 | 6200 | 4800 | 4800 | 4700 | 3200 | 3200 | 3200 | Speed (Rpm) |

| 28/710 | 28/710 | 22/560 | 22/560 | 22/560 | 20.5”/525 | 18”/458 | 18”/458 | 18”/458 | Wheel Pitch diameter (Inch/mm) |

| 6” | 6” | 4” | 4” | 4” | 4” | 2.5” | 2” | 2" | Inlet Size (ANSI, inch) |

| 20” | 12” | 8” | 10” | 8” | 6” | 4” | 4” | 4” | Exhaust Size (ANSI, inch) |

| 6440/4800 | 3490/2600 | 2550/1900 | 2010/1500 | 1475/1100 | 400/300 | 240/180 | 200/150 | 160/120 | Range Of capacities (hp/kW) |

| 2980/1350 | 2870/1300 | 2650/1200 | 2425/1100 | 2200/1000 | 2200/1000 | 880/400 | 840/380 | 770/350 | Shipping Weight (lb/kg) |

| 2TY | TY | 3SY | 2SY | SY | BSY | 3FY | 2FY | FY | Specifications (Max.) |

|---|---|---|---|---|---|---|---|---|---|

| 710/49 | 710/49 | 710/49 | 710/49 | 710/49 | 710/49 | 600/41 | 300/21 | 210/14.5 | Initial Pressure (psig/bar) |

| 770/410 | 878/470 | 770/410 | 770/410 | 770/410 | 770/410 | 716/380 | 644/340 | 550/288 | Initial Temperature (°F/°C) |

| 60/4 | 90/6 | 90/6 | 90/6 | 90/6 | 90/6 | 60/4 | 60/4 | 60/4 | Exhaust Pressure (psig/bar) |

| 6200 | 5000 | 6200 | 4800 | 4800 | 4700 | 3200 | 3200 | 3200 | Speed (Rpm) |

| 28/710 | 28/710 | 22/560 | 22/560 | 22/560 | 20.5”/525 | 18”/458 | 18”/458 | 18”/458 | Wheel Pitch diameter (Inch/mm) |

| 6” | 6” | 4” | 4” | 4” | 4” | 2.5” | 2” | 2" | Inlet Size (ANSI, inch) |

| 20” | 12” | 8” | 10” | 8” | 6” | 4” | 4” | 4” | Exhaust Size (ANSI, inch) |

| 6440/4800 | 3490/2600 | 2550/1900 | 2010/1500 | 1475/1100 | 400/300 | 240/180 | 200/150 | 160/120 | Range Of capacities (hp/kW) |

| 2980/1350 | 2870/1300 | 2650/1200 | 2425/1100 | 2200/1000 | 2200/1000 | 880/400 | 840/380 | 770/350 | Shipping Weight (lb/kg) |